Artificial Intelligence

for Quality Control

Artificial intelligence for quality control

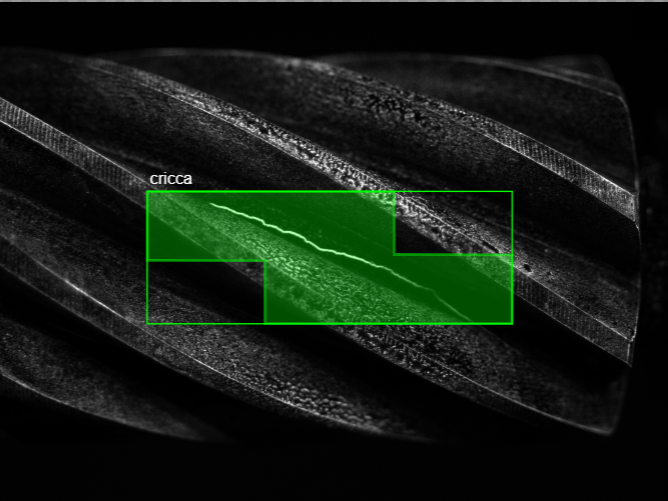

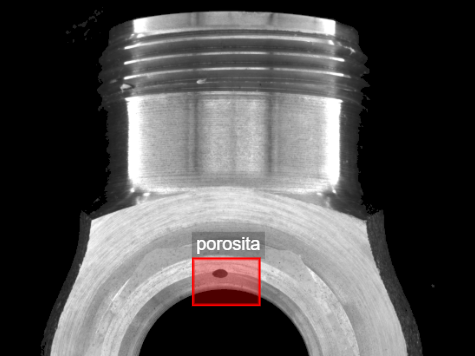

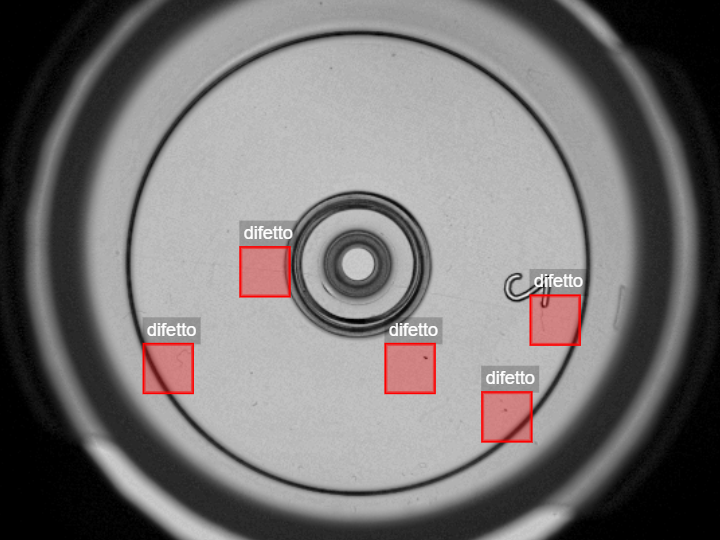

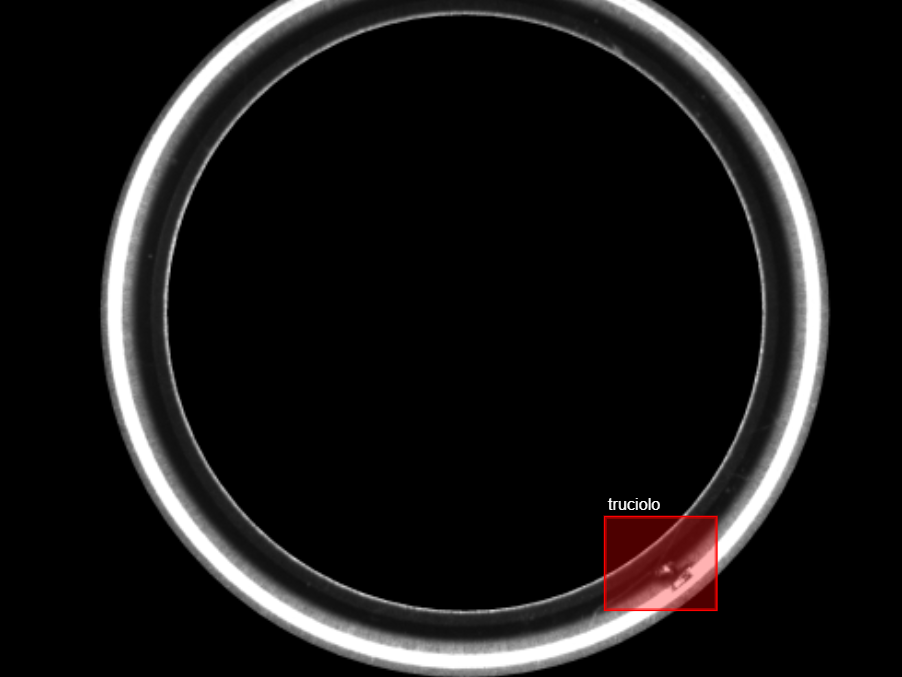

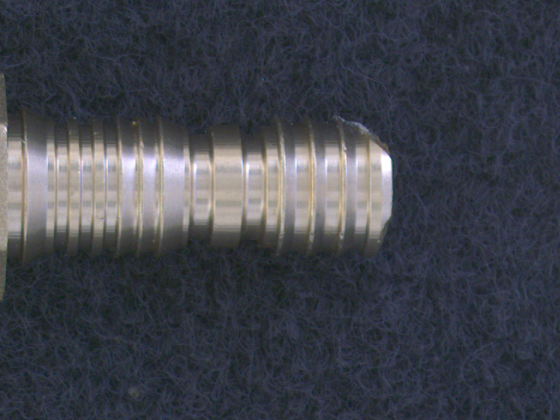

Our AI-based quality control system is highly flexible and can be used to detect and classify a wide range of defects, from the most common to the rarest and most difficult to detect. Because of the system's learning capability, our algorithm is able to learn from our customers' defective samples and increase the training dataset as new parts are inspected, ensuring the highest level of accuracy and reliability at all times.

At Advanced Robotics we believe in offering a complete service to our customers, starting with the defective samples, we develop an optical system suitable for the customer's part, the vision software and the robot program. With our experience and expertise, we can provide a customized solution for every need, ensuring maximum efficiency, reliability and quality of the finished product. Learn more about our quality control cell and how we can help your company achieve your business goals.

Productive Cases